MAXIMUM WEIGHT REDUCTION WITH MINIMUM WEAR

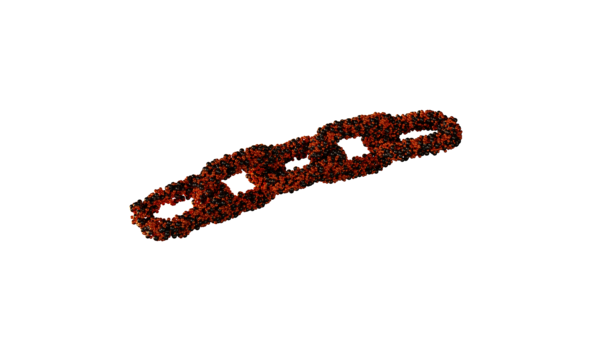

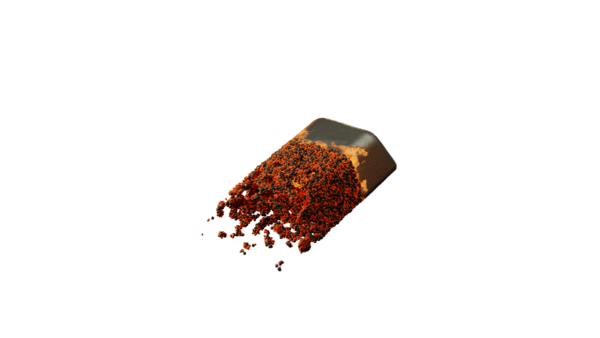

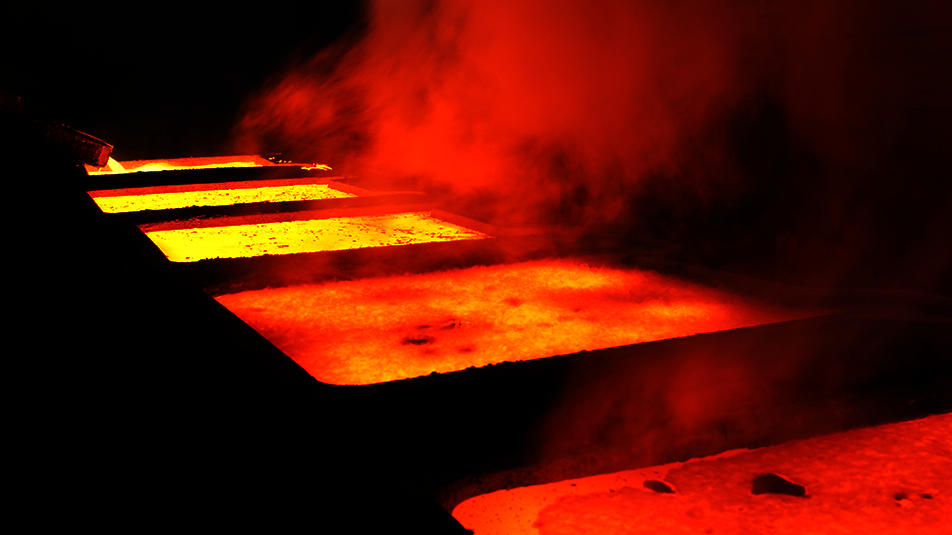

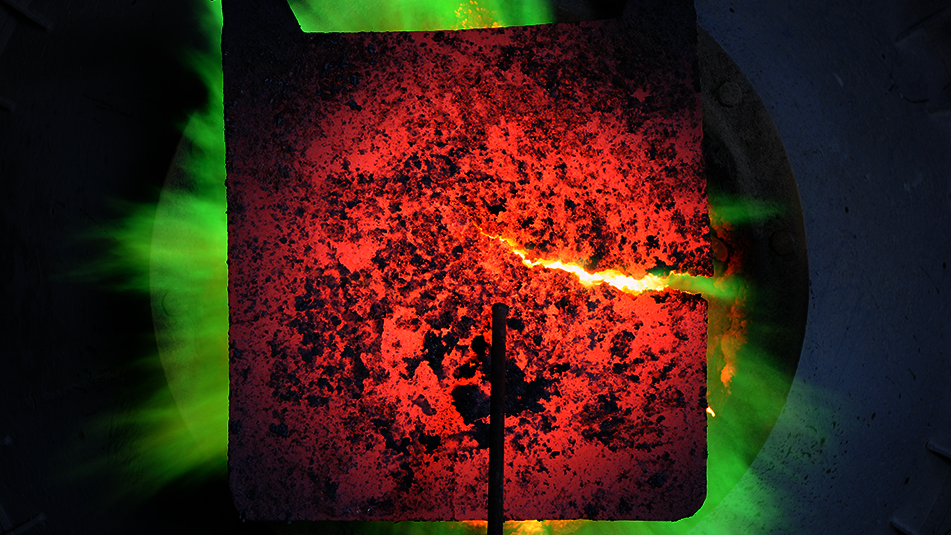

AMCs are reinforced aluminium alloys. Reinforcements can be fibers, whiskers and particles in various shapes and dimensions. We are involved in the production of particle-reinforced aluminium alloys. The used particles are primarily ceramics, but the reinforcing particles can also be metallic. We prefer silicon carbide (SiC) reinforced aluminium alloys, because there we see the greatest demand from the industry. While conventional processes for the production of metal matrix composites (MMCs) have so far been inefficient and difficult economically applicable, we have developed a rational casting process for the efficient series production of high-strength MMCs. We offer a homogeneous aluminium- matrix composite on an industrial scale.