REAL INNOVATIONS DO NOT HAVE TO BE HEAVY

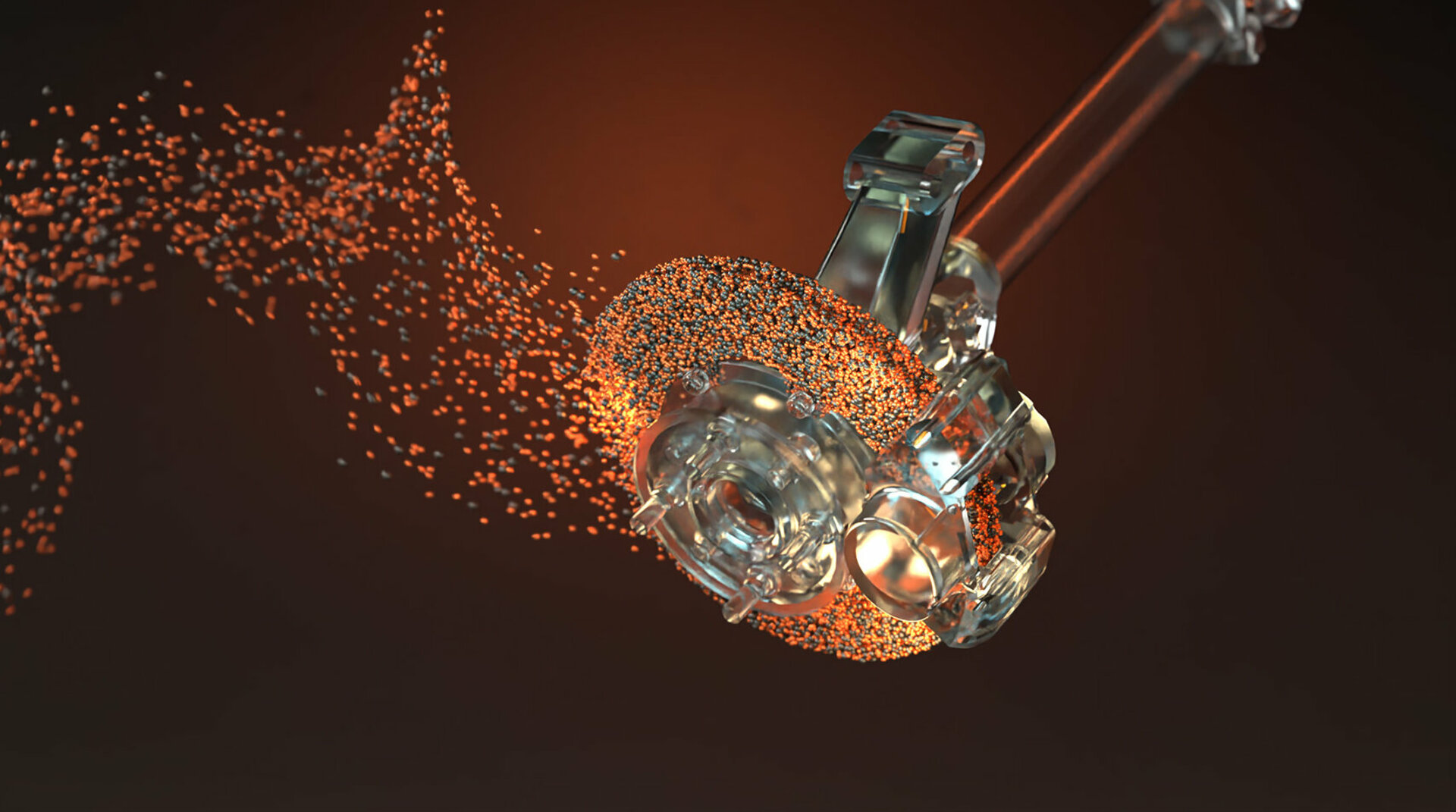

Where lightweight structural construction with traditional monolithic materials reaches their limits, you can go one step forward with the AMC material. For this purpose, we provide you with our AMC materials as semi-finished products for further forming processing. With our in-house continuous casting plant, we guarantee uninterrupted supply and extreme adherence to deadlines for your material procurement.