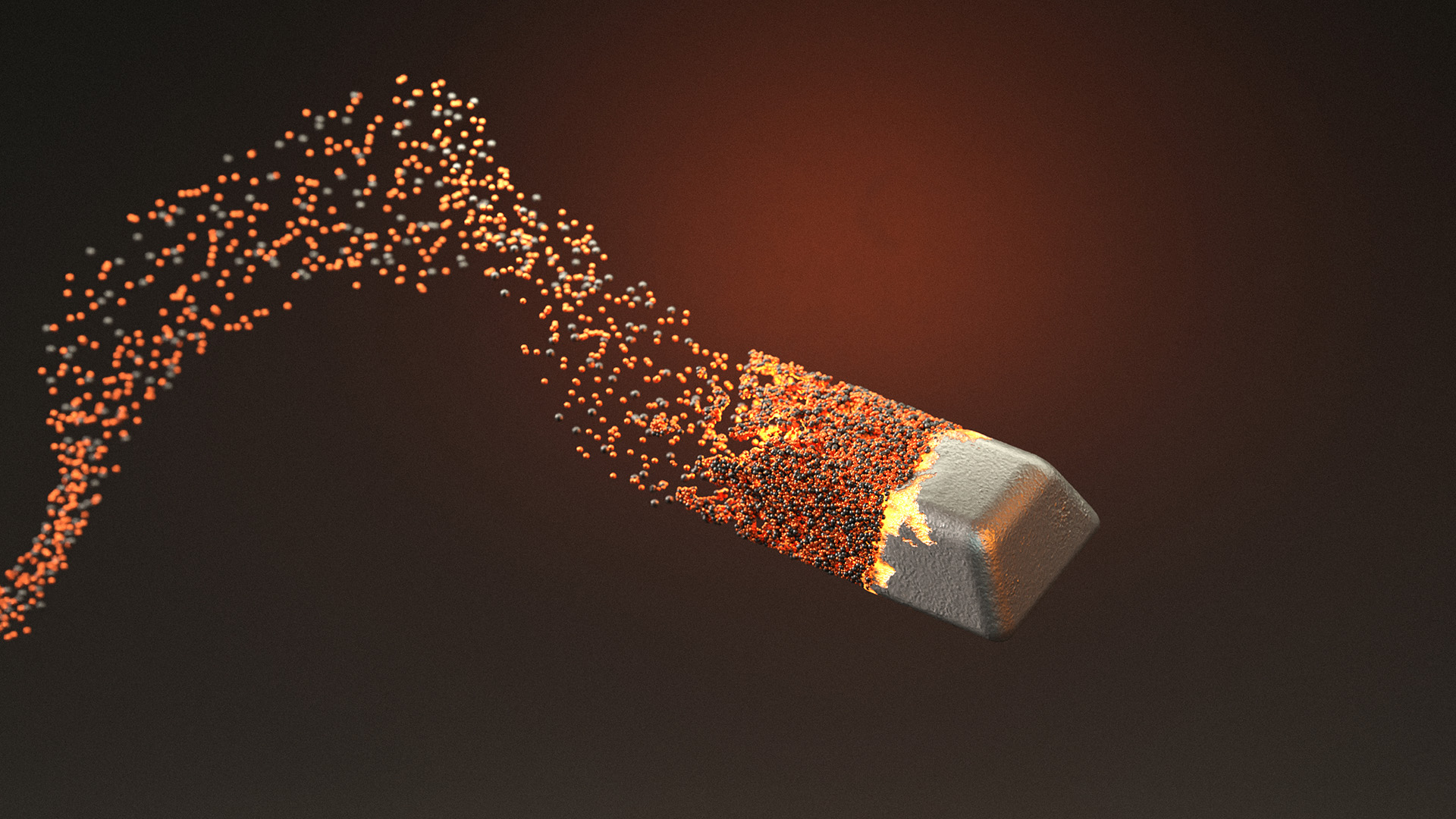

THE HEAVY WEIGHT FOR THE LIGHTWEIGHT TRENDS

Better, more efficient, lighter - along the value chain it is important to develop innovative and sustainable solutions for more energy efficiency and resource prodection. Trend topics such as sustainability and lightweight construction do not stop at the foundry industry. With AMCs from the CMMC GmbH, you can sustainably extend your technological lead without having to make extensive investments in your plant configuration.