IT COULDN’T BE EASIER!

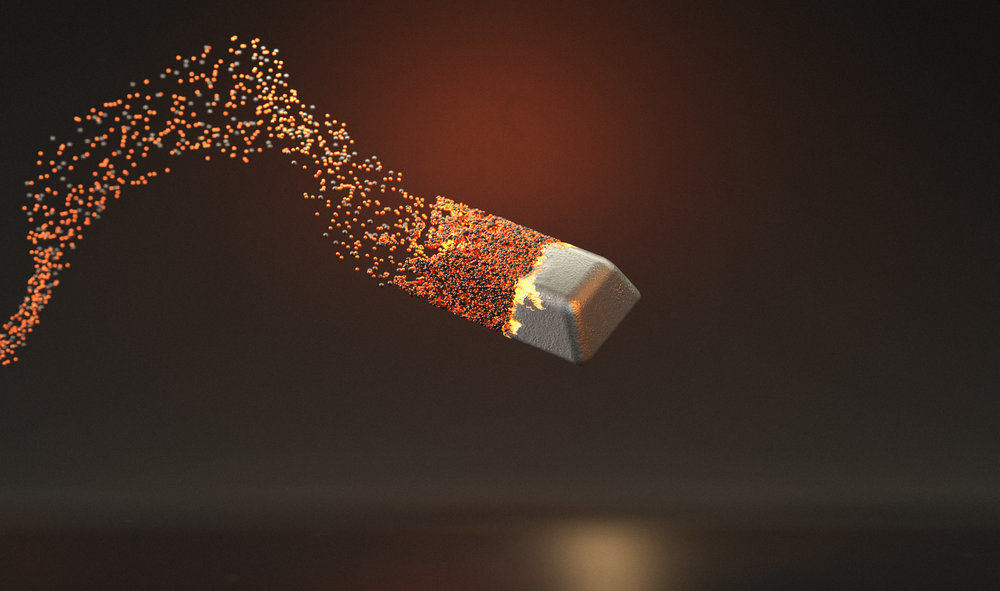

Welcome to CMMC GmbH - the innovator in the traditional foundry business. Ubiquitous demands for lightweight construction alongside energy and resource efficiency while exhibiting good application properties quickly stretch conventional materials to their limits. The solution is to use composite materials, e.g. aluminium matrix composites (AMC), which combine the strengths of disparate materials. However, the application of AMCs in the broader sphere has been hindered by the currently still-complex manufacturing processes and thus limited availability. CMMC GmbH is taking action to change that! With our novel, patented casting technology, we are taking AMC materials out of the niche and into broad application.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/0/7/csm_Nominierung-2024_d14ae583bc.jpg)